As the number of COVID-19 cases continues to escalate significantly throughout the nation, it is estimated that an astonishing 40,000 of face shields are used monthly at just one hospital.

{{ vm.tagsGroup }}

26 Mar 2020

2 Min Read

The Taylor's Team (Editor)

As the number of COVID-19 cases continues to escalate significantly throughout the nation, it is estimated that an astonishing 40,000 of face shields are used monthly at just one hospital.

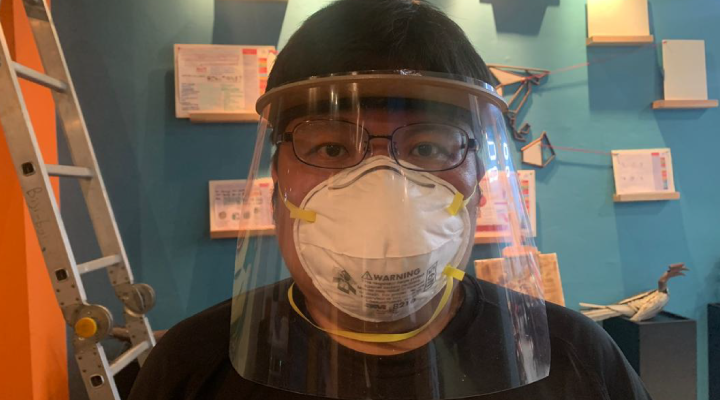

As one of the key items under Personal Protection Equipment (PPE), face shields which are used with N95 or surgical masks, are relied upon heavily by medical professionals, the police force, screening officials and the likes for full-face protection.

In response to the sheer volume that is needed, Taylor’s Me.reka Makerspace has started a decentralized production effort, in order to aid with the supply of the face shields: Taylor’s Me.reka Makerspace is a collaborative learning hub for academics, industry players and entrepreneurial communities, set up by Taylor’s University and Me.reka, the education arm under Biji-Biji Initiative.

The decentralized production plan is based upon the initial designs of the 3D printing community led by 3D Printing Malaysia and MRO. Subsequently, Mak Kwan Wuey from Makerzone & Fabspace KL, and She Tze Jin from Taylor's University ME.REKA Makerspace worked on improving the 3D printed design to evolve into a laser-cut version that is able to reduce the production time.

“Our front-liners bear a huge responsibility in keeping us safe by risking their own lives every day, especially during this challenging time. Following reports that supplies have fallen staggeringly short in the last few weeks, we immediately embarked on this initiative to produce face shields which we hope can keep them protected. It is timely that organisation and even the community band together to play their part in protecting these unsung heroes to battle this pandemic,” said She Tze Jin, from Taylor’s Me.reka Makerspace.

Taylor's Me.reka Makerspace have made about 1000 face masks in the first 3 days and aim to make 15,000 over the next 10 days. To further increase the level of production, Taylor's Me.reka Makerspace needs to raise about RM128,200 to pay for cost of materials such as acrylic sheets, 3D printer filament, elastic bands etc.

Taylor’s Me.reka Makerspace also encourage industry players with 3D printers, laser cutters or similar equipment to participate in this initiative, as well as public who can connect them with face shield manufacturers, plastic mould makers, suppliers of A4 transparent sheet (0.2mm), Acrylic sheets (4mm or 5mm), PLA filament, Elastic band(12mm - 20mm), sponge and hot glue.

The mass production is currently taking place at Taylor’s Me.reka Makerspace at Taylor’s Lakeside Campus, ME.REKA at Publika, Spectrum Laser Studio at Kepong and Admart Solutions at Muar.

The public can donate to Taylor's Me.reka Makerspace directly at:

| Account Name: | Biji Biji Design Sdn Bhd |

| Bank: | Alliance Bank |

| Account No: | 140820011062492 |

| Contact: | Juliana (014 366 6286) |

| Ambika (014 925 7203) |