We’re facing a problem in the healthcare field. Ir Dr Anis Suhaila’s research answers the root of the issue.

{{ vm.tagsGroup }}

13 Dec 2021

10 Min Read

Ir. Dr Anis Suhaila (Academic Contributor), Ailyn Low (Editor)

We’re facing a problem in the healthcare field. Ir Dr Anis Suhaila’s research answers the root of the issue.

According to the World Health Organisation (WHO), the recommended doctor-to-patient ratio is 1:500 with Malaysia’s ratio standing at 1:454 August last year. However, Malaysian Association of Private Colleges and Universities Deputy President and former Taylor’s University Deputy Vice Chancellor, Prof Dr Pradeep Nair stated that this didn’t account for the urban-rural divide. To add, not only is there an imbalance in the ratio of doctors, we’re also lacking in specialists.

Senior Lecturer and Programme Director Ir Dr Anis Suhaila Shuib from the School of Computer Science and Engineering*, shares why there’s a great need to train more surgeons to fix this problem. But with many expensive and unsustainable training procedures, is there a way to train specialists with more economical technology that doesn’t compromise on quality? Ir Dr Anis shares her solution and journey in this multidisciplinary project.

A: As a Malaysian, I felt that it was my responsibility to give back to the country. So, after my PhD, I returned to Malaysia and managed to collaborate on lots of projects with Hospital Universiti Kebangsaan Malaysia (HUKM), now known as Hospital Canselor Tuanku Muhriz. My first collaboration was with the radiology department.

I’m currently working on creating a blood mimicking fluid and blood flow for medical simulators. This idea, which started in 2005, stemmed from my PhD research, a multidisciplinary project between the engineering and medicine field. Back then, I was mainly working on computer simulation. We had a problem understanding blood flow which is important as there are many illnesses and fatalities related to it.

With my knowledge in chemical engineering and the movements of fluid, we utilised and adapted it to the human body. I investigated mainly the flow to find what condition poses risk or danger to a patient so it’d help doctors carry out diagnosis, make decisions, and disease management.

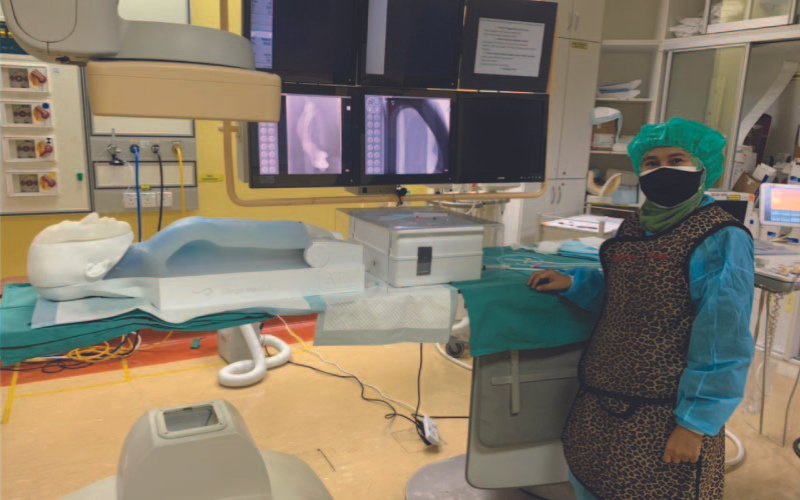

Ir Dr Anis Suhaila with a medical simulator.

A: There are many training procedures that surgeons, both new and expert, would have to go through — whether it’s on cadavers, animals, or even virtual reality training simulators. But unfortunately, they can be quite expensive and unsustainable. We came up with a newer, more economical solution — the 3D-printed medical simulator, an area that I’m mainly exposed to being in the engineering field.

According to the Brain Aneurysm Foundation, there are almost 500,000 deaths worldwide yearly with half the victims below the age of 50. Through this research, not only can we help treat brain aneurysm and other blood vessel related diseases more effectively, we’re also able to address the United Nations Sustainable Development Goal 9 on building resilient infrastructure, promoting inclusive and sustainable industrialisation, and fostering innovation and also Goal 3 that ensures healthy lives and promotes well-being for all at all ages.

With the medical simulator, surgeons aren’t only training their skills, they can also practise on a replica before the surgery, lowering the risk of any unforeseen circumstances, and allowing them to be more competent, resulting in more lives being saved. For example, a patient with a bulging blood vessel in the brain could burst and lead to stroke.

With this technology, we can extract the image of the artery and print a physical replica. The surgeon can then rehearse using that model before the actual treatment.

Unfortunately, though the simulator simulates what will happen, we can’t use actual blood. Previously they used water but it just doesn’t cut it. Using the blood mimic that represents the properties of actual blood allows surgeons to have a more realistic training experience. With these questions and problems posed by surgeons, we came up with the technique of this blood mimic and that was the start of my new venture!

Hopefully, upon the completion of this, we’d be accepted for future interventional neurosurgery clinical training.

A picture of the blood mimic in use.

A: I’m always curious about different things and I wanted to apply the same knowledge into my specialisation even if it’s a new project. Even while I was doing my Master’s on self-heating behaviour of fat-containing food powder, specifically milk powder, we used the same knowledge that ultimately helped society. I feel that the application of fundamental knowledge is very widespread and we’ve to be innovative in how it can be applied when solving different problems.

When I started my PhD, I wanted it to be more challenging. I wanted to merge the understanding of engineering aspects into the medical field which is done through the flow of blood in the body. In engineering, you can control and set what you want a machine to do, what you want it to be. Similarly, with the flow of oil and gas, I can control the valves, pumps, and machines but it’s different for humans. You cannot control it; you simply have to deal with it. The complexity and the curiosity of how my existing knowledge could be applied here was the reason why I ventured into it.

Secondly, when we’re working in the medical field, we’re doing it for people — there’s extra satisfaction and motivation from it. Working with people, you would also be dealing with the empathy and sympathy aspects that motivates you to carry on. It’s something that isn’t just a scope of your career but serves humanity. Pursuing a PhD is the last bit of your formal education and I wanted to make it special. I’m glad I took up this project and was able to collaborate in this meaningful way to give back to society for the rest of my career.

A: We all have the responsibility to solve problems whether it’s by or for the public and/or the government. What we have in society is complex, we need everyone. Even as an engineer, I need others in my life. So when we focus on solving a real-world problem, we cannot work alone or only focus on our scope, which would be very small and the impact wouldn’t go far.

At the end of the day, we’ve to realise that our responsibility is towards other people which means we’ll have to face these real problems and deal with subjects that contain many other aspects. For me, multidisciplinary research is vital if we want to produce a good impact and solve the real conditions we live in.

Ir Dr Anis Suhaila and the team at Taylor's working together to create face shields and other PPEs.

A: It was last year at the start of the pandemic, where we were working from home and research couldn’t proceed. My collaborators approached me saying that they’ve encountered a problem at the hospitals, “We don’t have enough PPEs. Can we think of something to solve this?”

That’s when I started to leverage my network and different colleagues to help out — both from the School of Medicine and School of Computer Science and Engineering1. We had a short discussion and concluded, “In our research, we do 3D printing. Why don’t we just do it in our labs?”. With the permission from the Executive Dean and collaboration with Taylor’s Me.Reka Makerspace, we managed to produce lots of face shields and sent them out to urban and rural areas within the span of 3 months.

I never imagined that research collaboration would go beyond our work to include charity purposes. We even sold some of this to obtain more funds for charity to buy more materials to produce more PPEs!

Just through our research network, we’re able to respond to our collaborators at the hospital. That unexpected satisfaction of collaborating with others and our combined knowledge as a team resulted in something meaningful for the community. I continued working closely with hospitals. As of now, I’m engaged with a medical simulator company, Lönge Medikal Sdn Bhd, and performing research testing at Hospital Pengajar Universiti Putra Malaysia (HPUPM). That was the best moment for me.

A: Back then, chemical engineering was relatively new as compared to other engineering disciplines. Seeing that I enjoyed chemistry but felt that it’d confined me to the lab, out of curiosity and interest, I decided to go into chemical engineering. I wanted to have something that I could grow in although it needed a lot of courage. I was also motivated by different questions on how this could be profitable and put to good use for the country’s economy.

I was working in the industry for about a year before I went into academia. I got many valuable experiences while practising in the industry but I had the urge to learn more and to answer the questions I had. Because of that, I decided to further my studies and try something new. Once you’re in the academic line, your competency is based on your knowledge so that carried me throughout my whole academic career. Surprisingly my linkage with the industry grew even though I’m attached with educational institutions.

In fact, being an academic in the engineering field, I’ve collaborated with those in the industry and gained industrial experience by being involved in industrial projects. I’m now a Chartered Engineer (CEng) registered with the Engineering Council, United Kingdom. On top of that, I’m also a registered Professional Engineer awarded by the Board of Engineers Malaysia. Being able to contribute to society in many aspects, whether through education or research in health, is what pushes me forward.

A: I got hired for my first job as an engineer because the interviewer was impressed with my part-time experience. I never expected it actually. As a student, we’d work part-time while pursuing our degree to support ourselves, especially while we’re abroad. When I joined the manufacturing factory for garments packaging while studying in the United Kingdom, I was exposed to the manufacturing system and also dealt with many people which is something I didn’t get from my formal university setting.

In university, you’d typically befriend those from the same education background, that have a similar understanding as you. While working, I learned about process flow and teamwork at a much younger age. Even though it wasn’t a very technical job, I gained values that had a significant impact in my life. I had to deal with many levels of people in different languages. We developed an understanding and respect for people around us.

I’ve to admit that that experience also helped me to deal with people at an early stage of my life. As a fresh grad, we’re normally anxious about what we do but with that experience, it was easier to deal with the team that’s under you when you start working.

A: Be open towards global issues. As solution providers, don’t just do things for your own interest but also do it for the good of others. Sometimes when we face obstacles and our goals only focus on us, we won’t go far. Focusing on the greater good gives us the strength and motivation to carry on with the work we do, especially when we’re at different crossroads. This doesn’t just build your own careers but also instills meaningful values into your life. At Taylor’s University, we believe in purpose-led learning which is helpful in this aspect.

1 Important note: As of 2023, the School of Computer Science and the School of Engineering have become two separate entities. This separation allows each school to focus more deeply on their respective specialized fields while maintaining a collaborative spirit in multidisciplinary projects.