COVID-19 has impacted us in more than one way. From the way we are being educated to how we interact with the people (not physically) around us, and even the way we’re buying our supplies.

In the first few weeks of the coronavirus, shelves of toilet paper, hand sanitisers, and face masks were emptied worldwide from panic buying due to the rising fear among the public.

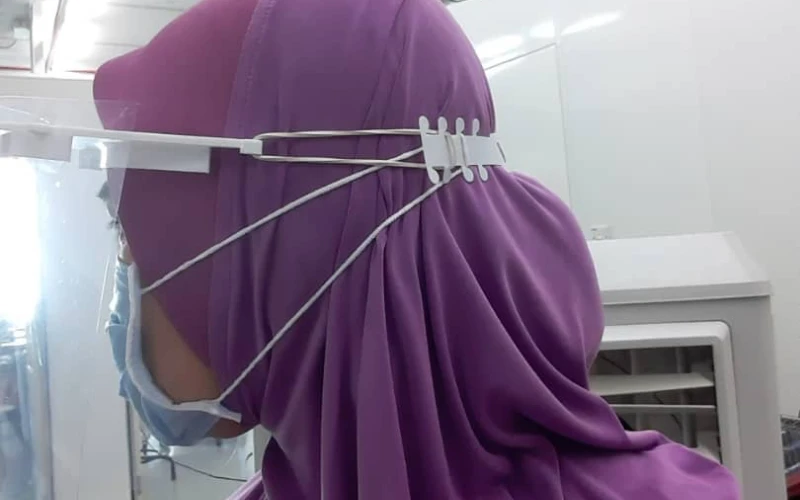

With the lack of products that are said to help in preventing the virus, these Taylor’s University schools were quick to come up with the necessary products to help protect our community and to flatten the curve, showing that necessity is truly the mother of invention.